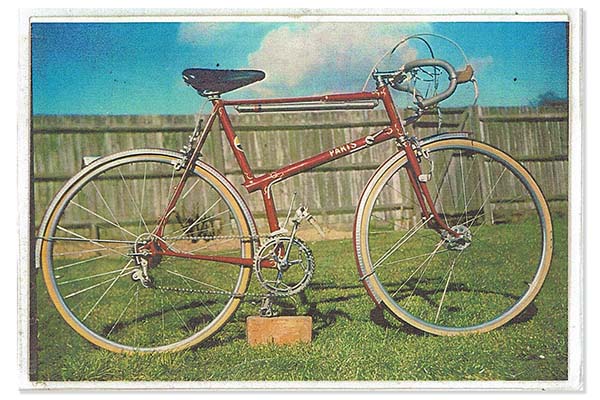

Paris Galibier

Truly timeless and an instantly recognisable classic

Interested in a bike?

Book an appointment

Handmade in Italy

Built by hand since 1948.

5 Year Warranty

We've got you covered.

Bike Fitting Included

Simply visit us in store.

Frame

Columbus SLX (except for twin top tubes), 2280g

Fork

Double plate steel fork crown, 400g

Complete Bike From

£3360.00 with Campagnolo Centaur

Fit

Race

Tyre Clearance

Up to 25mm

Frame Highlights

Solid point top eyes for stiffness

About this model

Truly timeless and an instantly recognisable classic, the Galibier packs charisma and a tenacious ride quality. Like its namesake mountain, the Col du Galibier, the Galiber bicycle is steeped in folklore. Introduced by Harry Rensch in 1947, the unique frame design caused a stir amongst post-war racing cyclists. It screamed continental flair and packed a punch with a shape created to eliminate whip, making acceleration and handling better. Our modern Galibier is a perfect reconstruction of one of the most iconic British framesets. The quality of the tubing improves upon Rensch's original selection, but the quirky design remains. Constructed from triple-butted, heat treated steel, the specialist tubes are made exclusively by Columbus for Condor. The high grade steel tubeset is accompanied by dropouts and fork crown that are stronger and lighter than the 1940s version, whilst the bi-laminations are now laser cut for precision detail.

| 49 | 52 | 55 | 58 | 61 | 64 | |

|---|---|---|---|---|---|---|

| Seat tube (centre to centre) [A] (cm) | 47 | 50 | 53 | 56 | 59 | 62 |

| Seat tube (centre to top) [B] (cm) | 49 | 52 | 55 | 58 | 61 | 64 |

| Top tube (horizontal) [C] (cm) | 51.5 | 52 | 53.5 | 55.5 | 57.5 | 59 |

| Seat tube angle [D] (cm) | 74 | 73 | 72 | 72 | 72 | 72 |

| Head tube angle [E] (cm) | 79 | 70 | 70 | 72 | 72 | 72 |

| Head tube length [F] (cm) | 7.5 | 9 | 11 | 14 | 16.5 | 19.3 |

| Chainstay length [G] (cm) | 44.5 | 44.5 | 44.5 | 44.5 | 44.5 | 44.5 |

| Bottom bracket height [H] (cm) | 26.5 | 26.5 | 26.5 | 26.5 | 26.5 | 26.5 |

| Stack (cm) | 46.8 | 58.5 | 50.4 | 53.9 | 56.3 | 59.5 |

| Reach (cm) | 38.1 | 38.1 | 38.1 | 38.1 | 38.1 | 39.7 |

Bottom bracket: BSA

Seat tube (internal): 27.2mm

Seat tube (external): 31.8mm

Front derailleur attachment: band-on

Headset: 1" threaded

O.L.D.: 130mm

If you would like to visit us in the store, here is how the process works.

1. Choose your model

We make a wide range to suit all styles and disciplines. Our full range is available to view online and in-store, but don't worry if you're not sure what's right for you — we're here to help!

2. Have a fitting

We'll ensure that you'll ride in complete comfort and get the best performance from your bike. If you can't visit us in store, we can help with the fit by phone or email.

3. Make it your own

We'll work with you to choose components that suit your requirements, right down to details such as handlebar tape colour. We are here to advise on everything.

4. We build it

We'll assemble your bike in London. Once built, we'll arrange a time and date with you for the handover, where we'll run through everything and help with anything else you may need.

If you can’t book an appointment to visit us in-store, we can help by phone, email, or live chat

Bi-lamination construction

A flat sheet of metal is cut by laser into the iconic Paris pattern. The metal is then formed by our craftsmen to sit exactly onto the tube and is fillet brazed into place. A bi-lam is stronger than a lug, as well as lighter. Before the gothic style bi-lams are fitted, the joints are fillet brazed, which makes for a stronger frame than the 1940s version.

Modern materials and performance steel

All of our triple-butted steel tubes are heat treated. Heat treated metal raises the yield strength for the entire tube, increasing dent and impact resistance. This enables the tube to be made with less material, creating a lighter frame.

Scalloped fork

The elegant fork with scalloped detailing and traditional curved design as would have been made in the 1950s. Made from high quality steel with stamp Condor logo in the dropouts.

Faithful to Harry Rensch's design

Its twin top tube and offset seat tube (designed to eliminate frame whip) was an instant favourite amongst riders. When building frames, the builder makes a diamond frame jig, then the builder tacks the frame together before welding. "It would be impossible to have a jig for the Galibier, so the frame has to be tacked by eye without the aid of the jig, which is where craftsmen come into their own."

Rust inhibiting treatment

After being welded, filed and cleaned, our steel frames are dipped in a rust inhibiting treatment. The treatment provides a degree of protection, particularly inside the frame, against corrosion caused by acidic substances (including water). Read more

You might also like

Classico Road

Classico Road

Classico Stainless

Classico Stainless