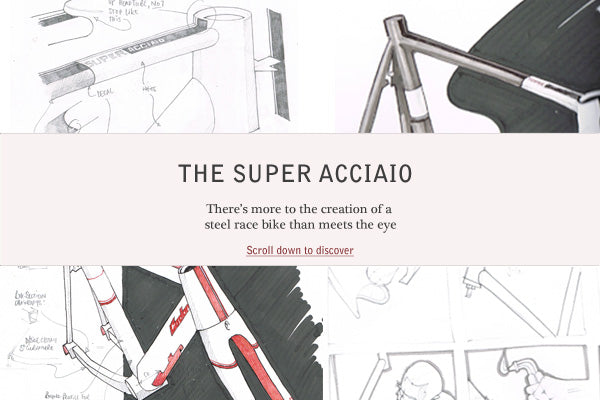

Oct 2010 - "The idea of a steel race bike was created on a whim.

Could we make a bike light enough to be raced, stiff enough to perform while retaining the characteristics of steel."

Sept 2013 - "In December 2012 we sat back down with Kristian and Tom from the team and decided to try and create something even better, now we have version two, lighter and faster."

Neil Manning, Production Director

In short, the Super Acciaio is a race tuned performance steel frame, with an oversized bottom bracket and tapered internal headset. This highly praised frameset is unique and original.

The design and production team are so proud of their efforts they challenge you to find a finished production frame anything like this one. Originally released at the 2011 Cycle Show, the Condor Super Acciaio was the first steel race bike available for retail featuring an oversized head tube and bottom bracket. The bike was extensively tested in 2010 and 2011 by Rapha Condor Sharp riders (now Rapha Condor JLT).

Condor returned to that tried and tested research format and created a better version of the frameset set for release this autumn.

The prototype frames were first tested in a factory environment in December 2012 before various incarnations were passed to former pro rider, Tom Southam, and Rapha Condor JLT lead rider, Kristian House, for review, while Rapha Condor JLT sprinter, James McCallum, used a version of the new Super Acciaio during the 2013 Tour Series.

Twelve months on after more exhaustive testing and prototyping we have sat back down with Super Acciaio Designer Ben Spurrier and Production Director Neil Manning reflect to reflect on the Super Acciaio version one and the new version two built in partnership with Columbus.

What is the bike's background?

Neil Manning: Five years ago there were a number of steel bikes in the range but nothing that was comparable to the carbon models being ridden by our and team and their competitors. The idea of a steel race bike was created on a whim. Could we make a bike light enough to be raced, stiff enough to perform while retaining the characteristics of steel? We did, and then it snowballed.

How was the original idea received?

Neil Manning: Once prototype one was built and painted we mentioned it to the team riders who are old enough to have started their careers on steel -Kristian House, Dan Craven and Tom Southam. Their response was really positive, they all wanted to ride it. Dan Craven rode the second prototype at the Smithfield Nocturne. He asked to take it to Italy, for the mid season break.

On his return to England he rode the bike named ‘The Steely Dan' and placed 2nd to Kristian House in a Premier Calendar one day race, a good podium for the bikes and team.

What makes the new Super Acciaio special?

Neil Manning: As an industry we've all learnt that a tapered headtube improves stiffness, especially when sprinting but also enables better control through tight twisting descents and on race finishing circuits.

We have taken a tried and tested formula and refreshed it. The latest incarnation retains the tapered bottom bracket and the frame is now 200g lighter and uses a carbon fork which is 50g lighter than the previous model.

What are the underlying themes in the design, both the frame shape and livery?

Ben Spurrier: When designing a new colour way for the second generation Super Acciaio we wanted something bold and fresh but timeless and in keeping with the Condor family. Fluorescent Red is a colour that was used on Condor steel race bikes in the 90's and looks as good now as it did then. The bike carries a blend of simple classic elements which are complimented by some more contemporary graphic devices reflecting the cutting edge race machine the Super Acciaio is.

Why partner with Columbus?

Neil Manning: Columbus is one of the oldest and most reknown steel tubing makers, they are a progressive company always looking to innovate and like Condor they are a family-run business too. In the 1930s they made steel-framed furniture designed by people like Marcel Breuer and Mart Stam. Columbus were the first to build a chair that had an enitrerly continous construction, this was only possible thanks to the seamless steel tubing they had developed.

In the early 1980s Columbus developed SLX and it was more advanced than any steel tube previously in existence. It became the choice of tube for any professional road racer because of the ingenious reinforced fillets added to the butted sections of the tube. This made the tube much stiffer and enabled it to be lighter, importantly it could take way more abuse.

Working with a company with such a strong pedigree is great because they are up for a challenge.